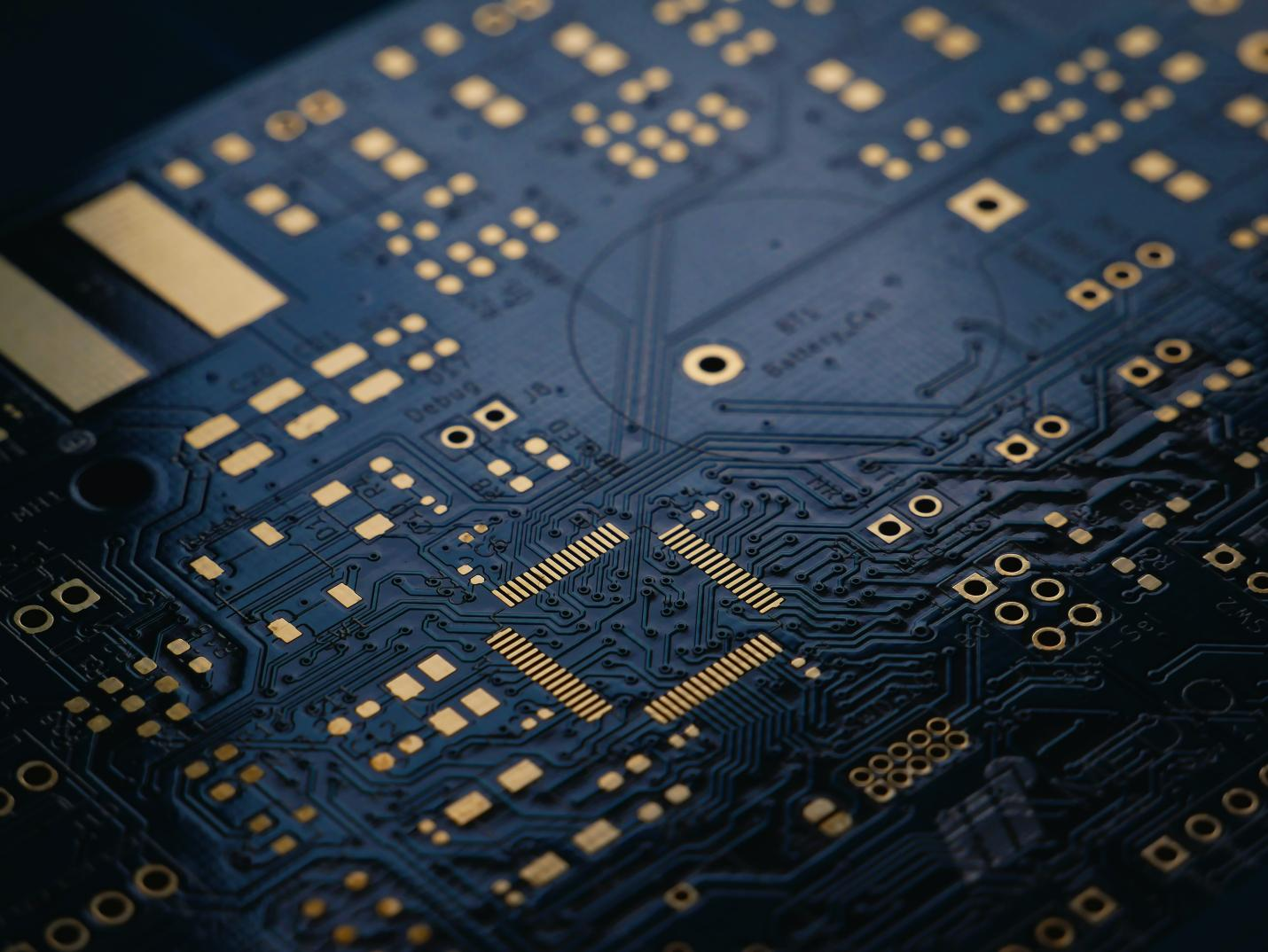

Prioritizing quality and speed is important when choosing reliable Printed Circuit Board (PCB) and PCB assembly (PCBA) services. When it comes to this, the seasoned PCB and PCBA manufacturer JingHua is a top choice. With a commitment to quality and competitive costs, we offer a comprehensive one-stop service for PCB solutions and PCB assembly services, including component sourcing. Read on to explore the advantages of choosing our PCB and PCBA, their applications in various industries, and more.

(Copyright photo from https://unsplash.com/photos/pfR18JNEMv8)

Advantages of JingHua as a One-Stop Solution for PCB and PCBA

There are many key advantages of choosing us for PCB solutions and PCB assembly services. The following top 3 aspects highlight those advantages:

- One-Stop PCB and PCBA Manufacturing

As a one-stop PCB and PCBA manufacturer, we efficiently handle the entire process from component sourcing to manufacturing. This way, we streamline the production cycle, significantly reducing lead times. This integrated approach has many key benefits for our clients.

One key benefit is access to reliable parts suppliers. This helps ensure the use of premium-grade components in the manufacturing process. Furthermore, we also achieve great energy and cost savings by managing the entire supply chain, leading to competitive pricing for our clients. Last but not least, having a single point of contact simplifies communication and improves overall project management.

- In-house PCB Fabrication and Assembly Manufacturing

Our expertise in PCB design and high-standard manufacturing facilities make us an ideal choice for clients looking for in-house PCB fabrication and assembly. By controlling the entire process in-house, we ensure the highest quality standards. We hold various certifications which ensure the quality and reliability of our products.

In addition, our efficient manufacturing process allows for shorter delivery times without compromising quality, which is another great advantage as it allows for meeting the tight project deadlines of our clients.

- Flexible OEM and ODM Services

We also specialize in supporting OEM and ODM projects and services. As a PCB solutions provider, we cover the entire product development cycle. From sample making to mass production, our comprehensive services are customized to meet specific requirements.

Our expertise and flexibility allow us to efficiently handle everything from prototyping to high-volume production. This capability ensures that the specific needs of our clients are met throughout the development process, resulting in successful product launches and market competitiveness.

JingHua PCB Applications

PCB solutions find applications in many sectors, contributing to the reliability, efficiency, and functionality of a wide variety of electronic devices and systems. Their adaptability and versatility make them fundamental to the modern technological landscape. The most common PCB applications include:

- Consumer Electronics

These complex and compact devices rely on PCBs to provide connectivity, signal processing, power distribution, and user interface functionality.

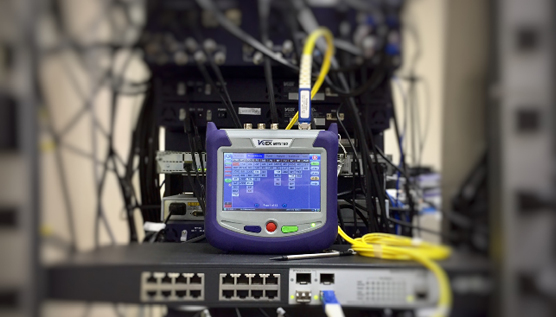

- Communications and Networking

PCBs play a key role in this industry, facilitating the transmission of voice, data, and video signals. They are used in network cards, modems, switches, routers, and telecommunication infrastructure equipment.

- Automotive Electronics

The automotive industry heavily relies on PCBs for many applications, including engine control units, advanced driver assistance systems, infotainment systems, dashboard electronics, and electric vehicle components.

- Industrial Automation

PCBs are crucial to industrial automation systems as they provide control and monitoring functions. They are used in programmable logic controllers, robotic systems, sensors, motor control units, etc.

- Medical Devices

Medical devices and equipment require highly precise and reliable PCBs to ensure accurate diagnostics, monitoring, and treatment. PCBs are used in devices such as CT scanners, MRI machines, pacemakers, patient monitors, etc.

Our PCBs are a go-to choice for various applications. We particularly specialize in industrial control, medical, and automobile industries:

- Industrial Control

We understand the requirements of the industrial control sector and offer PCB solutions that can withstand harsh operating conditions, temperature variations, and high levels of vibration to ensure seamless operation and efficient control systems.

- Medical

Our expertise in the medical sector enables us to meet stringent regulatory standards and deliver PCB solutions that adhere to medical device quality requirements. We use extensive R&D and quality control processes to make sure that our PCBs meet the highest standards of performance, reliability, and precision in the medical field.

- Automobile

We understand the demands of the automotive sector and specialize in delivering highly resilient and durable PCBs that meet automotive industry standards and contribute to the overall performance and safety of vehicles.

Conclusion

Overall, choosing a reputed PCB and PCBA manufacturer is crucial to ensure you enjoy the many advantages like speed and quality. As a PCB solutions provider, we are a recommended choice thanks to our ability to efficiently handle the entire PCB and PCBA process in-house, minimizing the overall project cost while satisfying the client’s specific requirements.

Our OEM and ODM services further add value to our clients by supporting custom requirements and enabling smooth transitions from prototype to mass production. With our expertise and applications spanning industrial control, medical, and automobile industries, we demonstrate our industry-specific knowledge and versatility in providing PCB solutions. Visit our website to learn more about us and discover the advantages of partnering with us for your PCB projects.