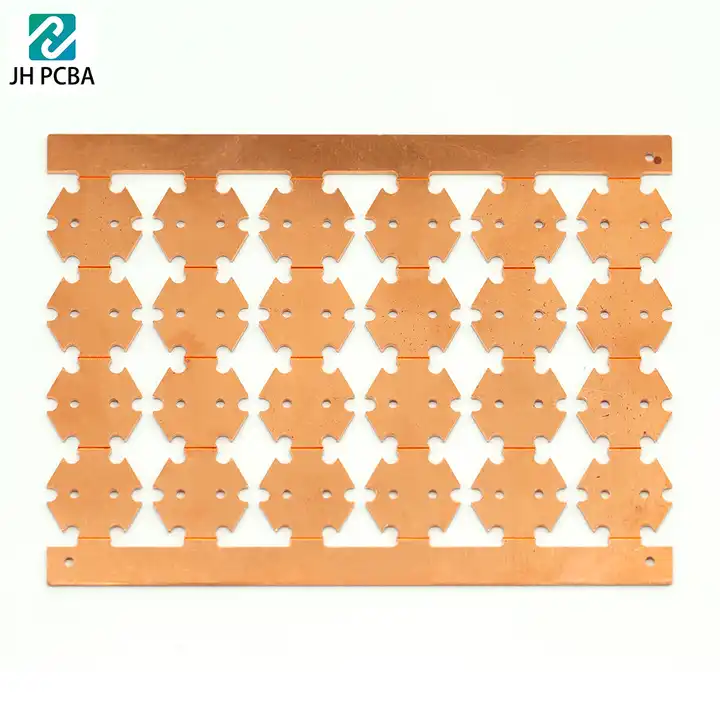

Category: Thick Copper PCB

Heavy Copper PCB Service

| Quantity (pieces) | 1-100 | 101 – 300 | 301 – 500 | >500 |

| Lead time (days) | 3 | 5 | 10 | Negotiation |

Jinhua Costom Service

- Rich Experience: One-stop Thick Copper PCB design & production factory for over 13 Years.

- 24H quickest lead time

- One-stop PCB & PCBA manufacturing service

- One-line quote and order status tracking, easy and reliable

- 24H*7 Non-stop production and support

- 100% On-time shipping with the best delivery from DHL/UPS/FedEx

- 60 professional engineers support

- Whole BOM List Purchase Management

- PCB design and engineering service

No MOQ requirement; Competitive prices; Professional team for OEM & ODM orders. Get quotes Now!

| Supply Ability | 60000 Piece/Month |

| MOQ | 1PCS |

| Certificate | ISO9001/ISO14001/CE/ROHS |

| Layer | 1-20 Layers |

| Base Material | FR-4 |

| Board Thickness | 1.6mm/Custom |

| Board Size | 250*1500mm/Custom |

| Copper Thickness | 1-13 OZ |

| Min. Hole Size | 0.2mm |

| Min. Line Width | 3mil |

| Min. Line Spacing | 3mil |

| Surface Finishing | HASL/OSP/Immersion Gold/HAL/LF |

| Material | FR4 /aluminum/ceramic CEM1 |

| Testing Service | 100% AOI Testing |

| Shipping | DHL UPS TNT Fedex DHL |

| Packaging Details | Bubble package, EPE package, ESD Bag, Vacuum Bag |

| Port | Shenzhen, China |

What is Thick Copper PCB?

Thick Copper PCB(Printed Circuit Board) boasts good conductivity and heat dissipation features, with copper thicknesses from 105 to 400 µm. As power requirements increase, the heavy copper PCBs are expected to transmit signals across the board. They are very suitable for power electronics, audio systems and renewable energy systems, allowing for high current handling and thermal management.

What are Benefits of Thick Copper PCB?

- Excellent Conductivity

The thick copper PCB boards increase electrical conductivity, allowing for higher current handling and better signal transmission. They help to connect various boards together to transmit currents. By enhancing the copper trace width, the thick copper PCBs can carry more capacity and handle higher current levels.

- High Temperature Management

Thick copper layers can overcome thermal cycles during electronics design, manufacturing and assembly. Due to superior thermal conductivity, these copper foil thickness PCBs are ideal for high-power electronic devices and systems.

- Durability

The PCBs with thick copper layers enhance the mechanical strength and durability of connectors and plated-through holes. They are more resistant to environmental stress, vibrations, and mechanical shocks, ensuring the board’s structural integrity and smooth electrical system.

- High Power Applications

Due to its high current handling, thick copper PCBs are designed for high-power applications, such as power supplies, amplifiers, and industrial equipment.

Thick Copper PCB Solution

Thick copper PCBs offer innovative and reliable solutions for high-power applications, such as amplifiers, audio systems, industrial equipment, and renewable energy systems. In the future, Thick copper printed circuit boards will make a significant impact on various industries.