PCB Assembly

One Stop PCB Assembly Service

With cutting-edge PCB assembling technology, we produce 8 million PCBA boards annually. Our electronic printed circuit board assembling services cater to vital sectors, including automotive, medical, lighting, and communications. If you need a few quick-turn PCB assemblies, Jinhua assembly service will be your best choice. By utilizing both onshore and offshore EMS services, our one-stop PCB assembly services enable you to reduce costs and speed up your time-to-market.

SMT Assembly

BGA Assembly

THT Assembly

Rigid-Flex Assembly

Mixed Technology Assembly

Turnkey PCB Assembly

PCB Assembly Process

We provide a one-stop service for PCB fabrication, PCB assembly and component sourcing.

Our CAM engineers have at least 5 years of experience in the PCBA test field. We will thoroughly check the customer’s PCBA design to optimize production. In particular, we need to check the customer’s GERBER data, as some missing, redundant or other non-conforming design defects will negatively affect subsequent PCB assembling. For example, the spacing design bewtten PAD and PCB component is too narrow, leading to short circuits.

Jinghua will conduct the following strict inspection of PCB, components, wires, and all other production materials before electronic PCB assembly. Based on quality requirements, Our IQC process will check incoming materials, like PCB boards, component shape, component parameters, pin number and spacing.

Based on the parameters of your GERBER file, CAD file, XY coordinate file, and BOM file, our solder paste printing machine, reflow soldering, BGA, X-RAY and other production and testing equipment will be programmed.

Printing is the first step in the SMT process, playing an important role in PCBA quality. We utilize GKG Gse automatic solder paste printing machine to achieve ±0.025mm, which boasts high precision and high stability. These advanced machines provide a strong guarantee for precision PCBA production.

After passing the in-line SPI inspection, the PCB board with solder paste is ready for mounting. Our mounter combination is YAMAHA brand YSM10 + YSM20R wiring combination, YSM20 mounting speed 300,600 dots/h, mounting accuracy: Chip/QFP/BGA ±0.035m, can meet the needs of fast and high precision mounting. The wired YSM10 multifunctional machine. They can mount components from 03015 to 45×45 m m, which can easily cope with devices in different shapes and sizes.

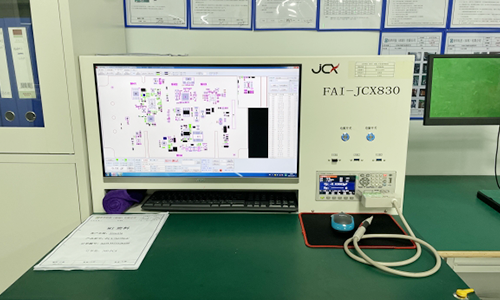

Before entering the reflow oven, the PCB board should pass the first piece tester test, to ensure that all the components are correctly placed, without placement error such as less parts, missing parts, reverse paste, pole reverse, more solder paste, and less solder paste.

JINTO lead-free reflow soldering has ten temperature zones, which can accurately manage the temperature for better soldering quality. After reflow soldering, the components can be firmly mounted on the PCB. To gain stable soldering performance, we will measure the oven temperature twice a day to find the most suitable temperature for the soldered products.

After reflow, PCBs need to be inspected again to ensure accurate and reliable soldering performance. Combined with the first inspection before reflow, the post-reflow inspection provides a double guarantee for quality assurance.

Clean the possible residual oil, fingerprints, solder paste and other dirt, then dry in the oven.

All assembling PCB boards are packed in static bags and shipped to customers. Unused components can be returned according to customer’s request.

SMT Lines

– 4 fully automatic and high-speed SMT assembly lines

– Monthly output up to 200-300 million chips

– Accurately welding 0201 and 01005 size electronic components, identifying BGA with 0.3mm distance and connector with 0.2mm distance

DIP Lines

– 2 DIP lines support Plug-in Assembly, Cable Assembly, Manual Soldering, Wave Soldering, and all kinds of Functional Tests

– strictly control the quality in every production process

PCB Assembly Inspection

– GKG-GSE printing machine,

– SPI inspection equipment

– FAI first tester, AOI, X-RAY, etc

PCB Assembly

JinHua provides comprehensive PCB assembly services, including PCB prototype, PCB Mass production, PCB circuit board assembly, and more. As a reliable PCB assembly manufacturer, our factory is equipped with SPI, AOI, X-RAY, and multiple functional tests that allow us to provide a quick-turn service without a broker.

PCBA Certification

Jinhua’s PCB assembling service has been recognized for its quality and compliance, with UL Certification, ISO14001 Environmental Management System Certification, ISO9001-2000 Quality Management System Certification, and IATF16949. By promoting PCBA technology and finding new methods, our best PCBA service leads to sustainable development and a greener future.

IATF16949 Automotive Certification

ISO9001

SGS and Alibaba Verified Gold Plus Supplier

Our Partners

Jinhua team has established a strong partnership with the original IC Producers including NXP ATMEl TI or Arrow Electronics, Avnet, Farnell, Future Electronics, Chip1stop, WPG, Digi-key and Mouser.Our professional sourcing service can offer big discount to you and save your time.

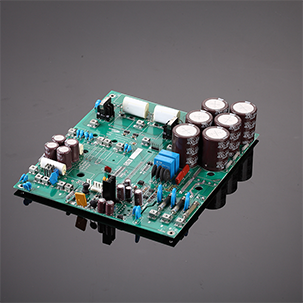

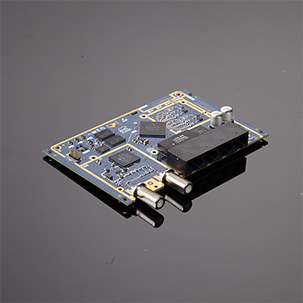

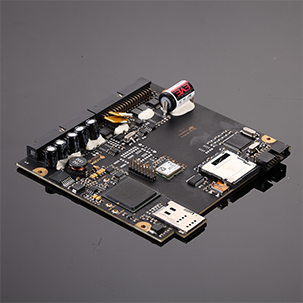

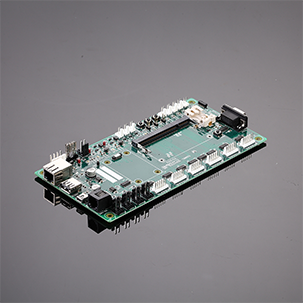

PCBA Product Show

Our PCB fabrication and assembly services provide a one-stop solution that includes material procurement, assembly, final packaging, logistics, and after-sales support, without MOQ requirements, thus saving you time and effort.

Here are some examples of successful PCBA products we created for our customers.

Get a Quote for Quick Turn PCBA Service

Whether you need a few quick turn prototypes or a few thousand production boards, Jinhua offers one-stop PCB assembly services for your boards at the scale you need.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Get A Quote

Wherever you are located in the world – please feel free to ask us anything from a technical question to a quote.